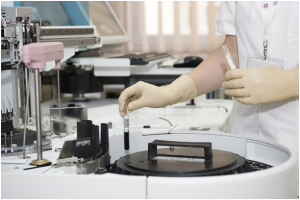

The production of generic drugs in India has skyrocketed, and the FDA has noticed. According to Reuters, India provides 40 percent of generic drugs to the United States, making it second only to Canada as a pharmaceutical powerhouse. A few particularly high-profile sanctions on Indian pharmaceutical manufacturers, however, have cast a pall over the entire industry.

Image Credit

Approvals Outnumber Sanctions

The infamous sanctions occurred in 2014, when some of India’s larger labs, including Ranbaxy, Sun Pharmaceuticals, and Dr. Reddy’s Laboratories, were banned by the FDA from importing drugs into the United States. This development caused stock prices in India to plummet and led to a rash of FDA inspections across the country.

However, at the same time that a few high-profile Indian companies gave the entire Indian pharmaceutical industry a bad name, other companies, such as Alembic, Amneal, and Aurobindo, were quietly churning out FDA-approved generic medications that were quickly imported to the US. It’s clear that honest companies that can withstand the harsh scrutiny of the FDA are able to thrive even in a more hostile global market.

Getting Clearance From the FDA

With the FDA turning a critical eye on Indian pharmaceutical companies, the idea of getting clearance to sell new generic drugs or medical devices can be daunting. This is where companies who provide TQT Studies come in thorough qt studies from richmond pharmacology. This company has trained staff that can help you through any needs you have and they help get medicines onto the market in a safe and controlled way. The FDA provides a list of requirements for the 510k for the approval of generic devices and the ANDA for the approval of generic drugs, but with the increased scrutiny on Indian pharmaceutical companies, additional help may be necessary. There are companies to help with FDA 510k or the ANDA so that honest companies can get the approval they need.

Companies must also make sure that their credentials are impeccable in order to withstand FDA scrutiny. Every day should be treated as a potential inspection day in terms of cleanliness and product quality control. In addition, companies must ensure that they properly document their developments, such as design controls, risk management, and QMS. By doing this, Indian pharmaceutical companies can be among the success stories rather than the cautionary tales.